How To Install Rear Bmx Brakes

This article volition discuss brake mounting and aligning for U-brake rim caliper systems.

i

Preliminary Info

The U-brake is a rim caliper brake plant on BMX freestyle and some vintage mountain bikes. The U-restriction fits to the frame above the rim. Both sides will have leap tension that pulls the pads from the rim. Arms are brought together either past housing to one arm or from a straddle wire carrier.

2

Caliper Installation

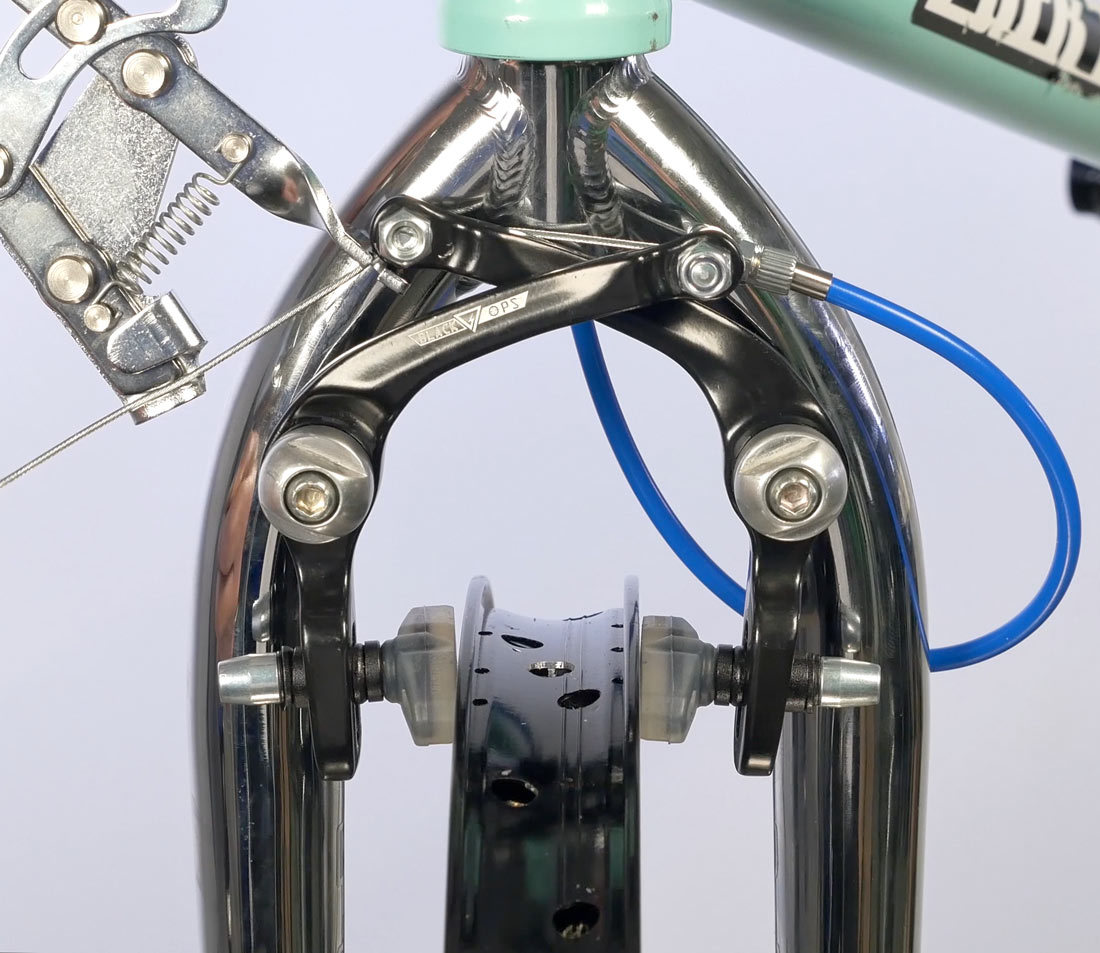

The U-brakes are mounted to the frame fittings. The brake mount studs are located above the rim braking surface. Grease only the outside of the stud.

Unlike cantilevers at that place is no leap hole. The arm springs are held by these outer fittings when the mounting bolts are tight. Install each arm onto the brake studs.

The two fittings exterior the brake artillery hold and command the arm return springs. A cone wrench volition fit the exterior of the spacer. Install a mounting bolt in each arm, run the bolts down, and secure. A common torque for the U-brake mounting commodities is 6 Nm.

3

Pad Aligning

Similar whatsoever rim brake, begin past moving the artillery and pads toward the rim and see how the pads are moving. The U-brake moves on an arc. The pads are moving up as they travel to the rim. That means the pads should exist set at the lower edge of the braking surface.

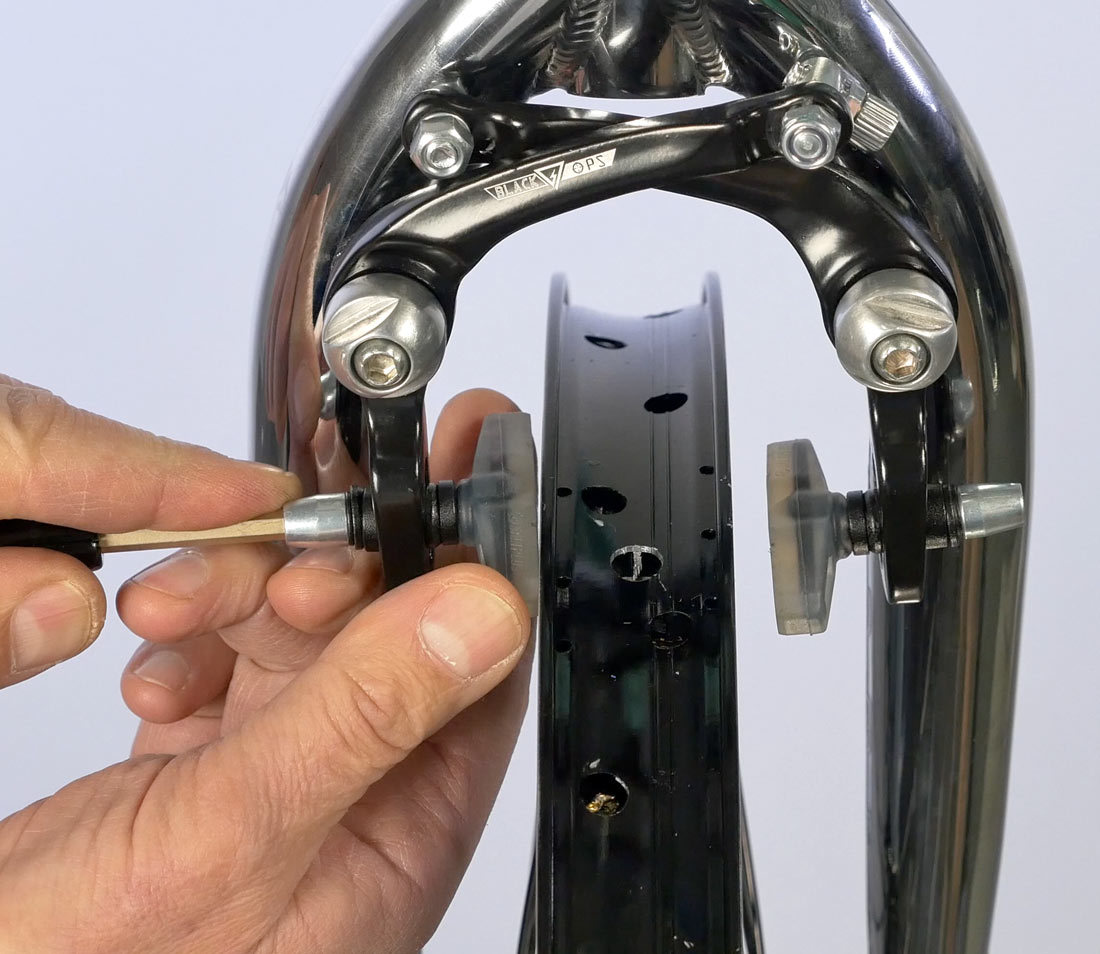

A common U-brake uses a ball and socket or convex-concave washer system. This washer arrangement allows motion of the pad in several planes before information technology is locked tight with the nut. This will allow us set toe, and too the vertical face square to the rim.

Notation: A useful technique on nigh U-brakes is to dorsum off the mounting bolts 1/4-turn to remove leap tension. This allows the arms to motility to the rim for pad adjustment without fighting leap tension.

Begin by loosening the brake pad mounting nut. When pushed to the rim, the washers will tend to self-align and makes setting the pad easy. The lower edge of the pad and U-brake on the lower edge of the braking surface. As the pad gets thinner it wears and moves upward. The front and dorsum border square to the rim. The face up of the pad and the face of the rim to be square.

Toe is a setting where there is a gap at the back of the brake pad and contact in forepart. Toe helps reduce the tendency for the arm to pull back and along quickly, causing squeal. A way to get toe is to loosen the mounting nut, concur the pad slightly at an angle in the back, secure the mounting nut, and so bank check for a slight gap. The process is repeated on the other side.

An additional technique to prepare toe is to apply a unproblematic shim behind the pad, such every bit a condom band. The rubber band volition create a gap as the pad is adapted. The rubber band is going to be removed and at that place should be with a slight gap the thickness of the rubber band.

Concord pad when doing final tightening on commodities or nut to forestall pad from rotating. A common torque is 4–5 Nm.

After the pads are set up, restore spring tension. Hold the outer fitting using a cone wrench, and rotate it slightly inwards. This creates spring tension. Motility the wrench a slight amount and secure the mounting bolt to approximately 6 Nm. Repeat the process on the other side, moving the wrench approximately the same corporeality. Fine-tuning spring tension volition exist done during centering.

4

Cablevision Attachment

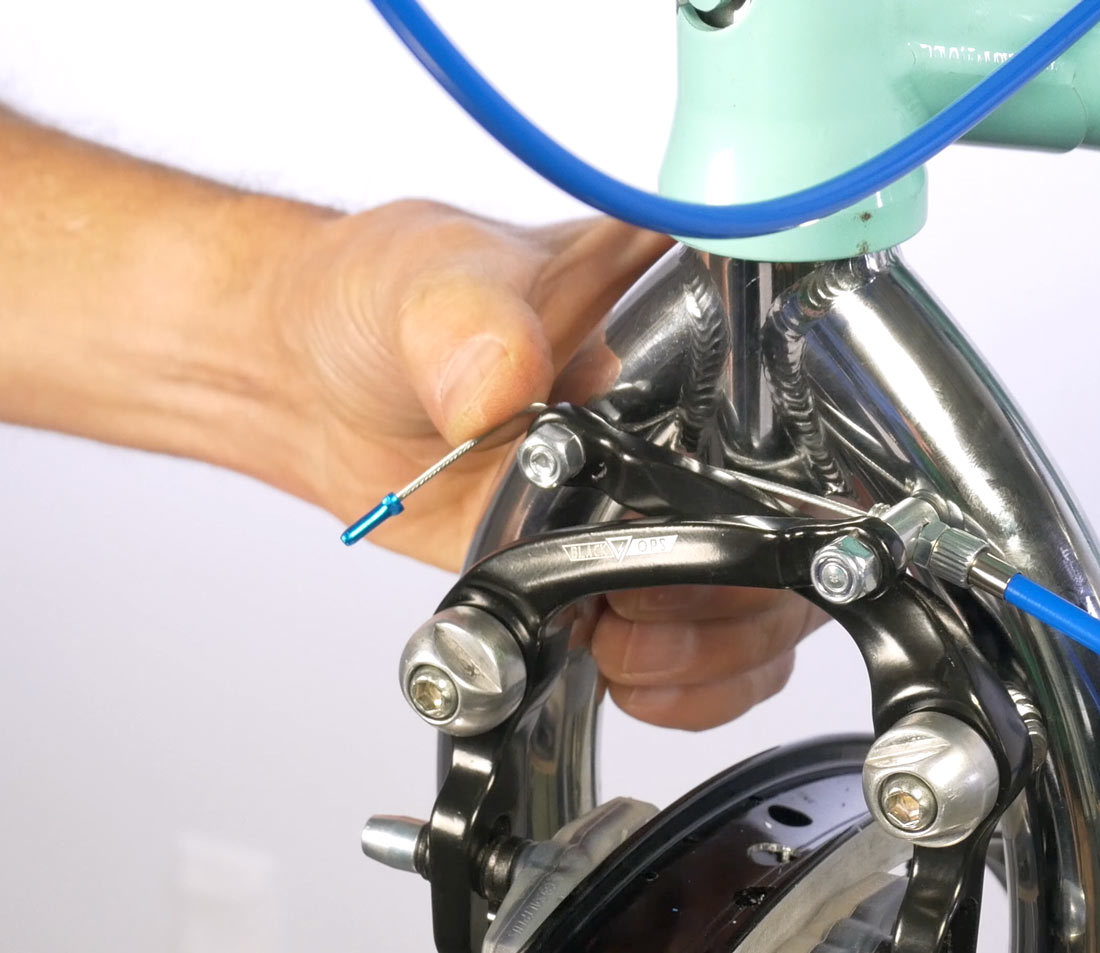

Cable zipper will vary with the pattern of the brake. Ane design uses a housing end on i arm, with the brake cable connecting to the other arm and a cable pinch mechanism. Feed the cable through the barrel adjuster, which acts as a housing stop. Guide the cable to the head of the the pinch bolt and through the hole. Draw the cable through until the housing is in the barrel adjuster, and now back out the barrel adjuster 2 or three turns to allow some fine-tuning of our pad clearance.

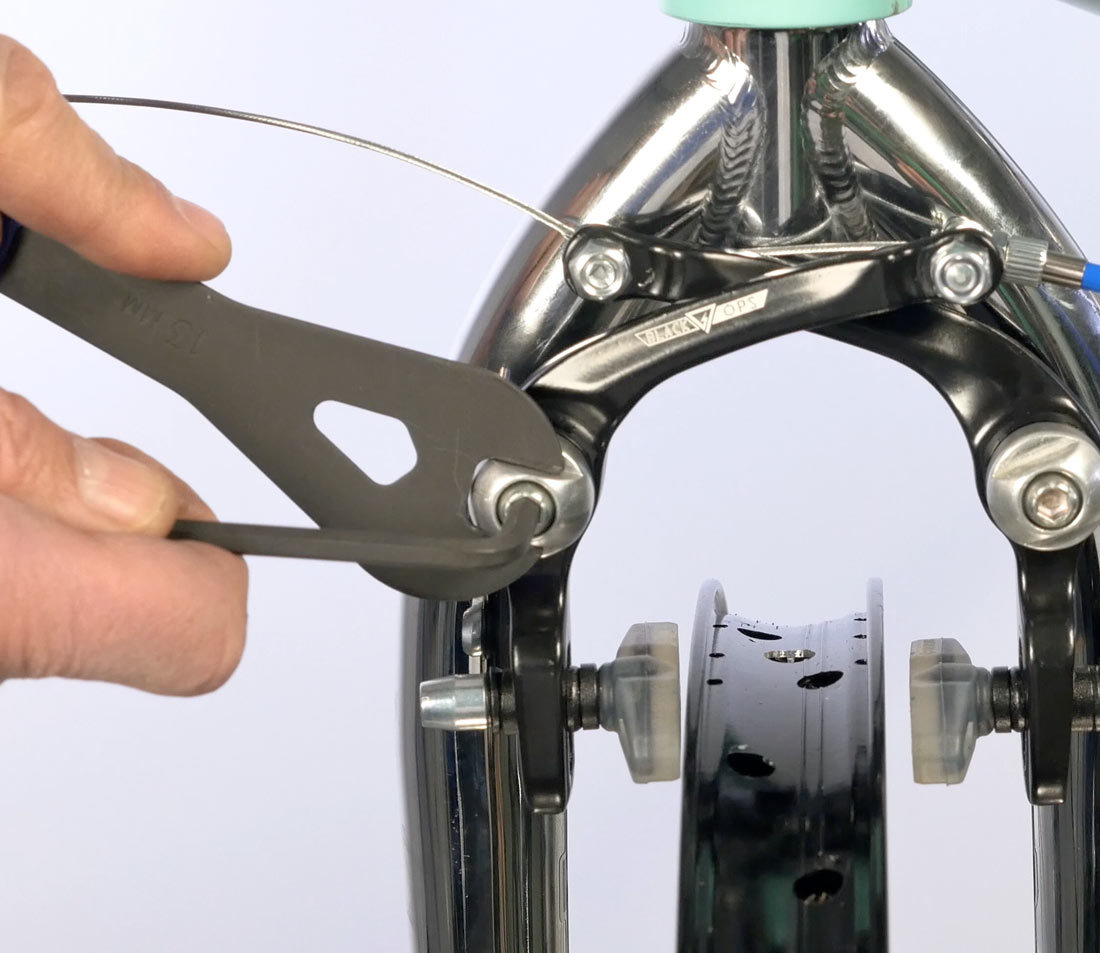

Draw the pads to the rim using a fourth mitt tool such every bit the BT-two. Engage the cable, lift ane arm and it pulls the pads to the rim. Do non clasp tightly or the brake will end upwardly too tight. The pads barely touching the braking surface is adequate. Secure the pinch commodities nut to about five Newton meters. This should be enough torque to flatten and pinch the cable.

Another system use a straddle wire carrier pulled by the chief cable from the brake lever. Begin by engaging the primary wire through the pinch commodities. Engage the straddle wire in the caliper artillery. Next, draw the pads to the rim.

An alternative to the 4th hand is to use a toe strap. Appoint the strap around both pads and draw them together to the rim. Next engage the straddle wire ends ane into each arm. Pull on the primary wire by mitt and push the straddle wire carrier forward. Hold and secure the compression nut, tightening to approximately v Newton meters. Release the strap and pull the lever with force, this will examination the security of the pinch mechanism and settle the cable into the organization.

5

Set Pad Clearance

Pull the lever with force to settle in the cable arrangement and to exam the security of the pinch bolts. Fix the pad clearance by feel at the lever. Too tight of a lever is going to engage instantly. Likewise tight will brand information technology hard to marshal without whatsoever rubbing. Besides loose a lever will not provide adequate stopping power.

To make changes to the pad clearance, use the barrel adjuster. Bringing the barrel adjuster out effectively lengthens the housing, draws out slack, and brings the pads closer to the rim.

half-dozen

Centering

Pad clearance is fix by changes to spring tension at the fitting of either arm. Move a pad further from the rim past increasing jump tension on that side. Using a cone wrench, hold the spring tension plumbing equipment, and loosen the mounting nut. Move the cone wrench inward and note when the rim to pad gap increment. Hold this position, secure the bolt, and examination information technology again. Repeat this process until in that location is an equal gap on both sides. On U-restriction systems, jump tension can be changed at either side.

7

Finishing Touches

Next trim the cable and install an end cap. Bend the end then information technology is out of the way.

Source: https://www.parktool.com/blog/repair-help/u-brake-service

Posted by: ellisoffearmed.blogspot.com

0 Response to "How To Install Rear Bmx Brakes"

Post a Comment